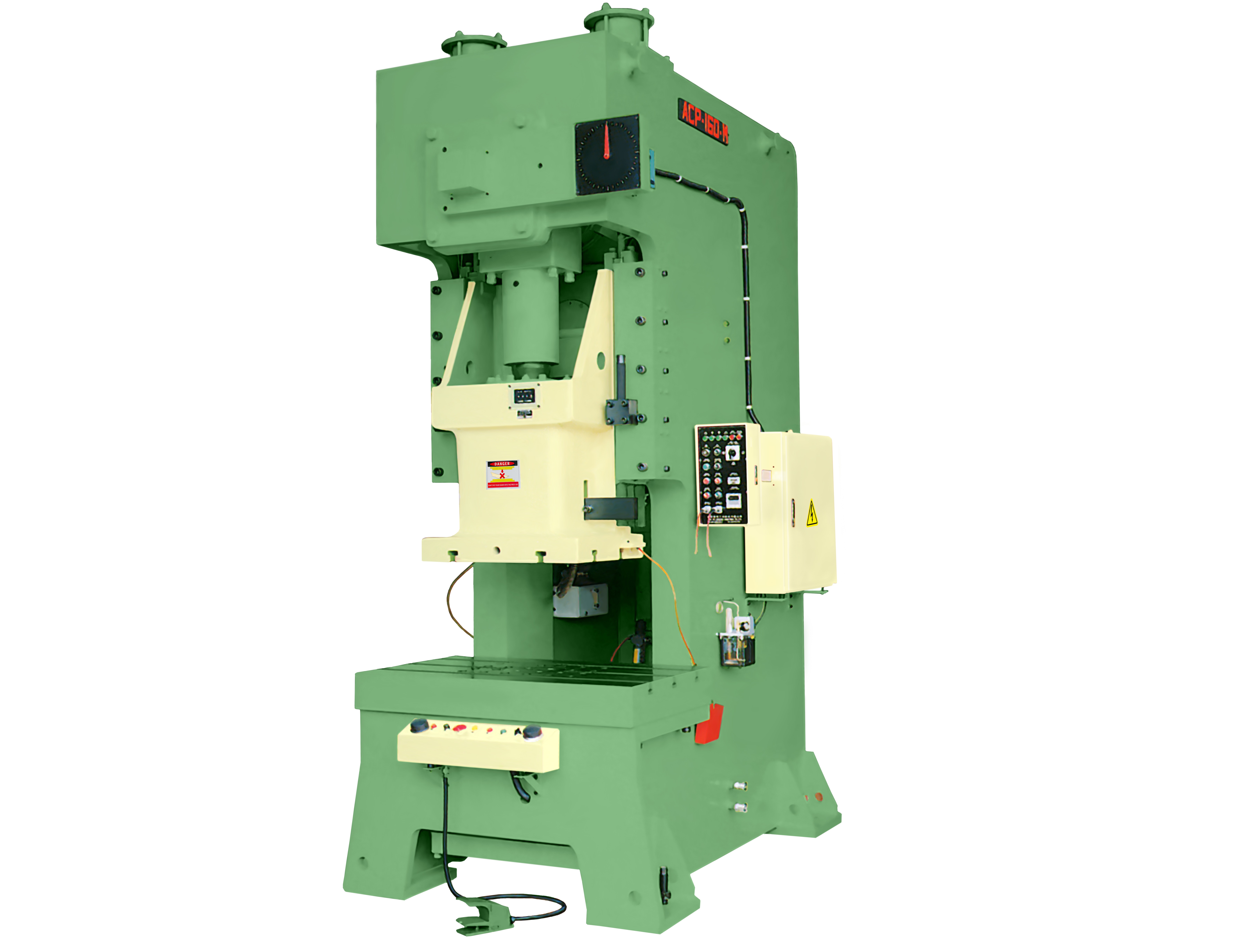

STRAIGHT SIDE POWER PRESS

| SPECIFICATIONS \ Model | TSP-45M | TSP-65M | TSP-85M | TSP-110M | TSP-160M | TSP-220M |

| Capacity ton |

45 | 65 | 85 | 110 | 160 | 220 |

| Speed per minute S.P.M |

70 | 60 | 60 | 50 | 40 | 35 |

| Length of stroke mm |

80 | 120 | 150 | 180 | 200 | 220 |

| Open height mm |

320 | 370 | 480 | 530 | 650 | 700 |

| Slide adjustment mm |

800 x 400 | 900 x 500 | 1000 x 550 | 1150 x 650 | 1250 x 760 | 1400 x 850 |

| Bolster area mm |

400 x 300 | 480 x 380 | 560 x 440 | 650 x 500 | 720 x 580 | 860 x 650 |

| Shank hole mm |

φ38 | φ50 | φ50 | φ50 | φ63.5 | φ63.5 |

| Hole of bolster plate mm |

φ100 | φ150 | φ150 | φ150 | φ220 | φ250 |

| Ram motor hp x p |

Manual | Manual | 1/2 x 4 | 1/2 x 4 | 1 x 4 | 1 x 4 |

| Main motor hp x p |

3 x 4 | 5 x 4 | 7.5 x 4 | 10 x 4 | 15 x 6 | 20 x 6 |

| Size of case mm L W H |

1340 1010 2700 |

1500 1030 3050 |

1670 1330 3330 |

1850 1450 3800 |

2250 1550 4250 |

2450 1680 4400 |

| Shipping weight kg |

4000 | 5200 | 6900 | 10000 | 17000 | 24000 |

FEATURES:

* All-steel welded structure of balanced frame and ram, furnace-stress-relieved before machining

The one-time process of the entire frame assures more accuracy

* Combination air clutch & brake is a low interstitial stress unit for giving efficiency greater and is

designed for trouble-free production and low maintenance cost

* An overload protector is adopted inside the slide as an overload safety device to protect the

machine damage and convenience work

* Slide is adjusted by manual (80 ton and bellow) and motorized, pneumatic slide balance device

keeps the balance of slide connection parts and die for smooth operation

* The crank angle indicator will show the crank position accurately and immediately wherever

operators need

* The die height indicator with a digital counter in graduations of +/- 0.1mm

* Automatic lubrication is accomplished by a full-flow, circulating, filtered system protected

by a safety switch.

STANDARD EQUIPMENT:

1. Motor and controller |

8. Slide knockout device |

| 2. Hydraulic overload protector | 9. Power take-off shaft |

3. Manual lubricator system |

10. Die height indicator |

4. Counterbalance |

11. Foot pedal switch |

5. Rotary cam limit switch |

12. Maintenance tool |

6. Crank angle indicator |

13. Leveling screws |

7. Magnetic stork counter |

14. Instruction manual |

CATALOG

CATALOG